一、产品概述:

YG型管道油泵的设计制造符合美国石油学会API610《一般炼厂用离心泵标准》和GB3215-82《炼厂、化工及石油化工流程用离心泵通技术条件》的有关规定。

1、可以不建泵房,在室外工作。

2、进出口法兰在同一中心线上,可直接安装在管道上,立式结构机泵一体,占地面积小,安装方便。

3、采用优质机械密封,轴端无泄漏,有效地减少了泵房的油气含量,改善了工作环境,提高泵高工作的安全可

靠性。

4、关键零部件选用优质新型材料,根据输送介质的腐蚀性和温度要求,提高了泵的工作可靠性和使用寿命。

5、选用防爆等级为dIIBT4的EX防爆电动机,具有优良的防爆性能。

二、型号意义:

三、使用范围:

该泵主要使用在管路增压,远距离输送汽油、煤油、柴油、航空油等油类,也可输送其它无腐蚀性的液体.

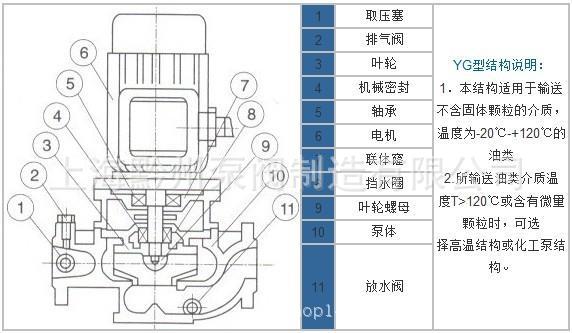

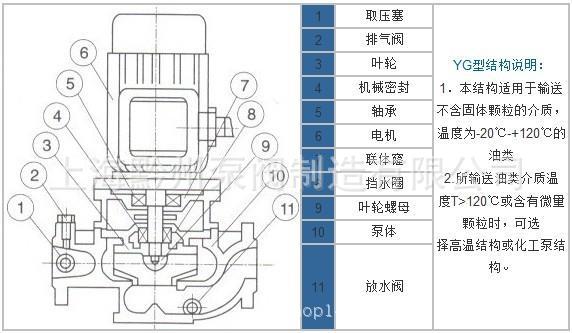

四、结构说明 :

五、性能参数:

|

型号

Model

|

流量

Flow

(m3/h)

|

扬程Head

(m)

|

转速

Speed

(r/min)

|

功率

Power

(KW)

|

电压Voltage

(V)

|

汽蚀余量NPSHr

|

重量Weight

(kg)

|

|

20YG-160

|

2

|

32

|

2900

|

0.75

|

380

|

2.3

|

38

|

|

25YG-125

|

3

|

20

|

"

|

0.75

|

"

|

2.3

|

35

|

|

25YG-160

|

3

|

32

|

"

|

1.1

|

"

|

2.3

|

44

|

|

25YG-160A

|

2.6

|

25

|

"

|

0.75

|

"

|

2.3

|

40

|

|

32YG-125

|

4.5

|

20

|

"

|

0.75

|

"

|

2.3

|

38

|

|

32YG-160

|

4.5

|

32

|

"

|

1.5

|

"

|

2.3

|

49

|

|

32YG-160A

|

4

|

25

|

"

|

1.1

|

"

|

2.3

|

43

|

|

32YG-200

|

4.5

|

50

|

"

|

3

|

"

|

2.3

|

68

|

|

32YG-200A

|

4

|

40

|

"

|

2.2

|

"

|

2.3

|

58

|

|

40YG-100

|

6.3

|

12.5

|

"

|

0.75

|

"

|

2.3

|

36

|

|

40YG-125

|

6.3

|

20

|

"

|

1.1

|

"

|

2.3

|

45

|

|

40YG-125A

|

5.5

|

16

|

"

|

0.75

|

"

|

2.3

|

38

|

|

40YG-160

|

6.3

|

32

|

"

|

2.2

|

"

|

2.3

|

52

|

|

40YG-160A

|

5.5

|

25

|

"

|

1.5

|

"

|

2.3

|

42

|

|

40YG-200

|

6.3

|

50

|

"

|

4

|

"

|

2.3

|

79

|

|

40YG-200A

|

5.5

|

40

|

"

|

3

|

"

|

2.3

|

67

|

|

40YG-250

|

6.3

|

80

|

"

|

7.5

|

"

|

2.3

|

123

|

|

40YG-250A

|

5.5

|

65

|

"

|

5.5

|

"

|

2.3

|

115

|

|

40YG-100(I)

|

12.5

|

12.5

|

"

|

0.75

|

"

|

2.3

|

40

|

|

40YG-125(I)

|

12.5

|

20

|

"

|

1.5

|

"

|

2.3

|

47

|

|

40YG-125(I)A

|

10.5

|

16

|

"

|

1.1

|

"

|

2.3

|

40

|

|

40YG-160(I)

|

12.5

|

32

|

"

|

3

|

"

|

2.3

|

67

|

|

40YG-160(I)A

|

10.5

|

25

|

"

|

2.2

|

"

|

2.3

|

56

|

|

40YG-200(I)

|

12.5

|

50

|

"

|

5.5

|

"

|

2.3

|

110

|

|

40YG-200(I)A

|

10.5

|

40

|

"

|

4

|

"

|

2.3

|

88

|

|

40YG-250(I)

|

12.5

|

80

|

"

|

11

|

"

|

2.3

|

175

|

|

40YG-250(I)A

|

10.5

|

65

|

"

|

7.5

|

"

|

2.3

|

125

|

|

50YG-100

|

12.5

|

12.5

|

"

|

0.75

|

"

|

2.3

|

39

|

|

50YG-125

|

12.5

|

20

|

"

|

1.5

|

"

|

2.3

|

49

|

|

50YG-125A

|

10.5

|

16

|

"

|

1.1

|

"

|

2.3

|

42

|

|

50YG-160

|

12.5

|

32

|

"

|

3

|

"

|

2.3

|

68

|

|

50YG-160A

|

10.5

|

25

|

"

|

2.2

|

"

|

2.3

|

58

|

|

50YG-200

|

12.5

|

50

|

"

|

5.5

|

"

|

2.3

|

108

|

|

50YG-200A

|

10.5

|

40

|

"

|

4

|

"

|

2.3

|

88

|

|

50YG-250

|

12.5

|

80

|

"

|

11

|

"

|

2.3

|

175

|

|

50YG-250A

|

10.5

|

65

|

"

|

7.5

|

|

2.3

|

125

|

|

50YG-100(I)

|

25

|

12.5

|

"

|

1.5

|

"

|

2.5

|

55

|

|

50YG-100(I)A

|

20

|

10

|

"

|

1.1

|

"

|

2.5

|

48

|

|

50YG-125(I)

|

25

|

20

|

"

|

2.2

|

"

|

2.5

|

76

|

|

50YG-125(I)A

|

20

|

16

|

"

|

1.5

|

"

|

2.5

|

66

|

|

50YG-160(I)

|

25

|

32

|

"

|

4

|

"

|

2.5

|

85

|

|

50YG-160(I)A

|

20

|

25

|

"

|

3

|

"

|

2.5

|

84

|

|

50YG-200(I)

|

25

|

50

|

"

|

7.5

|

"

|

2.5

|

146

|

|

50YG-200(I)A

|

20

|

40

|

"

|

5.5

|

"

|

2.5

|

144

|

|

50YG-250(I)

|

25

|

80

|

"

|

15

|

"

|

2.5

|

193

|

|

50YG-250(I)A

|

20

|

65

|

"

|

11

|

"

|

2.5

|

182

|

|

50YG-315(I)

|

25

|

125

|

"

|

30

|

"

|

2.5

|

330

|

|

50YG-315(I)A

|

20

|

100

|

"

|

22

|

"

|

2.5

|

270

|

|

|

型号

Model

|

流量

Flow

(m3/h)

|

扬程Head

(m)

|

转速

Speed

(r/min)

|

功率

Power

(KW)

|

电压Voltage

(V)

|

汽蚀余量NPSHr

|

重量

Weight

(kg)

|

|

65YG-100

|

25

|

12.5

|

2900

|

1.5

|

380

|

2.5

|

54

|

|

65YG-100A

|

20

|

8

|

"

|

1.1

|

"

|

2.5

|

48

|

|

65YG-125

|

25

|

20

|

"

|

2.2

|

"

|

2.5

|

68

|

|

65YG-125A

|

20

|

16

|

"

|

1.5

|

"

|

2.5

|

58

|

|

65YG-160

|

25

|

32

|

"

|

4

|

"

|

2.5

|

85

|

|

65YG-160A

|

20

|

25

|

"

|

3

|

"

|

2.5

|

72

|

|

65YG-200

|

25

|

50

|

"

|

7.5

|

"

|

2.5

|

116

|

|

65YG-200A

|

20

|

40

|

"

|

5.5

|

"

|

2.5

|

106

|

|

65YG-250

|

25

|

80

|

"

|

15

|

"

|

2.5

|

192

|

|

65YG-250A

|

20

|

65

|

"

|

11

|

"

|

2.5

|

180

|

|

65YG-315

|

25

|

125

|

"

|

30

|

"

|

2.5

|

340

|

|

65YG-315A

|

20

|

100

|

"

|

22

|

"

|

2.5

|

325

|

|

65YG-100(I)

|

50

|

12.5

|

"

|

3

|

"

|

3.0

|

74

|

|

65YG-100(I)A

|

44

|

10

|

"

|

2.2

|

"

|

3.0

|

64

|

|

65YG-125(I)

|

50

|

20

|

"

|

5.5

|

"

|

3.0

|

116

|

|

65YG-125(I)A

|

44

|

16

|

"

|

4

|

"

|

3.0

|

95

|

|

65YG-160(I)

|

50

|

32

|

"

|

7.5

|

"

|

3.0

|

118

|

|

65YG-160(I)A

|

44

|

28

|

"

|

5.5

|

"

|

3.0

|

108

|

|

65YG-160(I)B

|

40

|

24

|

"

|

4

|

"

|

3.0

|

88

|

|

65YG-200(I)

|

50

|

50

|

"

|

15

|

"

|

3.0

|

190

|

|

65YG-200(I)A

|

44

|

44

|

"

|

11

|

"

|

3.0

|

180

|

|

65YG-200(I)B

|

40

|

28

|

"

|

7.5

|

"

|

3.0

|

130

|

|

65YG-250(I)

|

50

|

80

|

"

|

22

|

"

|

3.0

|

260

|

|

65YG-250(I)A

|

44

|

70

|

"

|

18.5

|

"

|

3.0

|

218

|

|

80YG-100

|

50

|

12.5

|

"

|

3

|

"

|

3.0

|

74

|

|

80YG-100A

|

44

|

10

|

"

|

2.2

|

"

|

3.0

|

64

|

|

80YG-125

|

50

|

20

|

"

|

5.5

|

"

|

3.0

|

110

|

|

80YG-125A

|

44

|

16

|

"

|

4

|

"

|

3.0

|

90

|

|

80YG-160

|

50

|

32

|

"

|

7.5

|

"

|

3.0

|

120

|

|

80YG-160A

|

44

|

28

|

"

|

5.5

|

"

|

3.0

|

118

|

|

80YG-160B

|

40

|

24

|

"

|

4

|

"

|

3.0

|

18

|

|

80YG-200

|

50

|

50

|

"

|

15

|

"

|

3.0

|

186

|

|

80YG-200A

|

44

|

44

|

"

|

11

|

"

|

3.0

|

176

|

|

80YG-200B

|

40

|

38

|

"

|

7.5

|

"

|

3.0

|

126

|

|

80YG-250

|

50

|

80

|

"

|

22

|

"

|

3.0

|

260

|

|

80YG-250A

|

44

|

70

|

"

|

18.5

|

"

|

3.0

|

220

|

|

80YG-250B

|

40

|

60

|

"

|

15

|

"

|

3.0

|

200

|

|

80YG-315

|

50

|

125

|

"

|

37

|

"

|

3.0

|

380

|

|

80YG-315A

|

44

|

113

|

"

|

37

|

"

|

3.0

|

376

|

|

80YG-315B

|

40

|

101

|

"

|

30

|

"

|

3.0

|

358

|

|

80YG-350

|

50

|

150

|

"

|

55

|

"

|

3.0

|

530

|

|

80YG-350A

|

44

|

142

|

"

|

45

|

"

|

3.0

|

420

|

|

80YG-350B

|

40

|

135

|

"

|

37

|

"

|

3.0

|

360

|

|

80YG-100(I)

|

100

|

12.5

|

"

|

5.5

|

"

|

4.5

|

118

|

|

80YG-100(I)A

|

88

|

10

|

"

|

4

|

"

|

4.5

|

88

|

|

80YG-125(I)

|

100

|

20

|

"

|

11

|

"

|

4.5

|

174

|

|

80YG-125(I)A

|

88

|

16

|

"

|

7.5

|

"

|

4.5

|

125

|

|

80YG-160(I)

|

100

|

32

|

"

|

15

|

"

|

4.5

|

190

|

|